If you’ve ever struggled with inserts coming loose during a slotting operation, keep reading. How about inconsistent slot widths, fumbling with awkward screws and inserts on a slotting cutter, or having to use a piece of shim stock to pry wedged chips from deep inside a slotted workpiece?

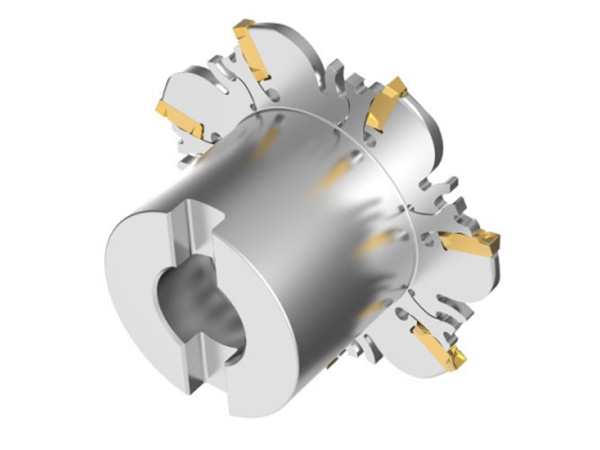

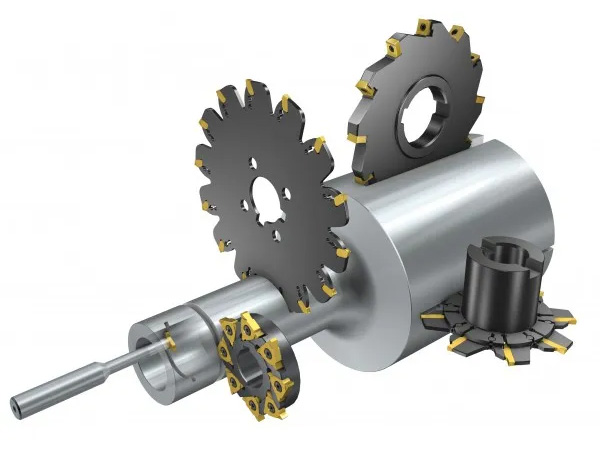

These are just a few of the problems machinists face when trying to cut narrow slots and grooves, but thanks to the newly introduced Kennametal Narrow Slotting (KNS) cutter, the days of “slotting dread” are over, according to the company.

Slotting is a common machining practice. Scott Etling, Kennametal’s director of global product management for indexable milling, lists many applications where the KNS excels. Automakers can use the new cutter to separate cast exhaust manifolds and steering components.

Equipment manufacturers can cost-effectively mill the clamping slots on shaft supports and stock collars. Power generation and electronics companies now have a more productive way to machine keyways, add heatsink grooves, yokes and O-ring grooves.